At Qingdao Guanshan Industry Co., Ltd., continuous research and development of raw material formulas and production processes play a key role in our rapid growth. We have a team of engineers with over 40 years of experience in liquid rubber R&D, as well as experts from top automotive manufacturers. This helps us improve formulations, optimize production, and explore new solutions.

Additionally, we’ve partnered with the Rubber College of Qingdao University of Science and Technology for advanced rubber formulation testing. These ongoing improvements have earned us the trust and recommendations of customers in the custom-molded rubber product industry. We’re proud to collaborate with companies like SAIC-GM and LS Tractor.

Quality control (Q.C.) during production is crucial for ensuring consistent product quality. At Qingdao Guanshan Industry Co., Ltd., we’ve implemented a comprehensive system of production monitoring, in-process checks, clear production specifications, and continuous improvement plans. Each production shift includes 5-8 random inspections, with additional checks during nighttime shifts to ensure quality.

Through thorough inspections and sampling, we can quickly identify and resolve technical issues, reduce scrap rates, and improve production efficiency. We use a combination of electronic and hand tools to ensure accurate measurements, and all our instruments are tested, approved, and regularly maintained by the Qingdao Industrial and Commercial Administration.

To keep improving, our managers and technicians hold weekly meetings with production staff and quality control teams. Together, we analyze any issues that arise, identify solutions, and work on improving our production processes.

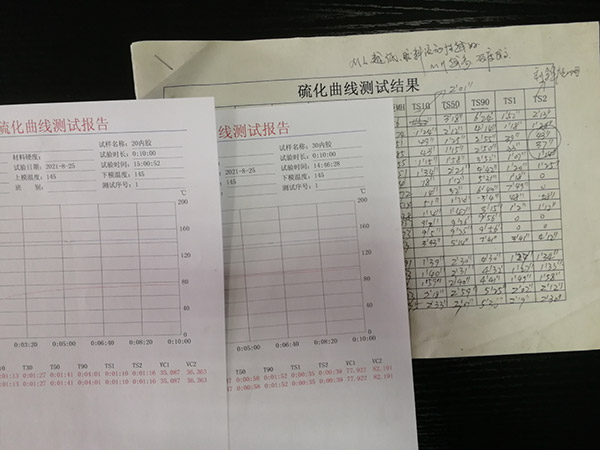

Since its establishment, Qingdao Guanshan Industry Co., Ltd. has invested in building advanced laboratory facilities. Today, we have a full range of testing equipment, including a rotorless vulcanizer, anti-fatigue tester, compression deformation tester, density meter, hardness tester, voltage testing equipment, anti-aging equipment, and a low-temperature testing device that operates at -40°C.

We also collaborate with the Rubber College of Qingdao University of Science and Technology to conduct advanced tests, including oil resistance, acid and alkali resistance, fire resistance, flame retardant performance, and high-temperature combustion testing.

With continuously updated testing equipment and strong partnerships for research and development, Qingdao Guanshan Industrial Co., Ltd. offers unmatched capabilities in raw material formula improvement and product testing. This gives our customers confidence in the high quality of our custom-molded rubber products.

Supporting local market development for our distributors and channel partners is a core commitment of our entire company, not just the sales department. To ensure end users trust our products, we work closely with distributors to help them persuade customers to make faster purchasing decisions.

We collaborate with trusted organizations like SGS and PONY to test the performance of our products. As a result, we can quickly provide key certifications such as ROHS, REACH, PAH, and fire-resistance, assuring our customers of the highest quality and safety standards.

If you’d like to obtain test templates used by other customers, please feel free to contact us. We will be happy to provide you with a reference document. To comply with NDA terms, any customer-specific information on these templates will be hidden.

We take quality control seriously, and we understand the critical importance of precision in every product we manufacture. To maintain the highest standards, we partner with Anzheng Testing, a trusted third-party testing and calibration provider.

Every year, Anzheng Testing conducts a comprehensive calibration of all our measuring equipment. This ensures that all our instruments are functioning accurately, providing reliable measurements for production processes and product inspection. By doing this, we guarantee that every part, from rubber seals to custom molds, meets our strict quality standards and your specific requirements.

This annual calibration is an essential part of our commitment to precision, efficiency, and consistency in production, and it reflects our dedication to delivering only the best products to our customers.